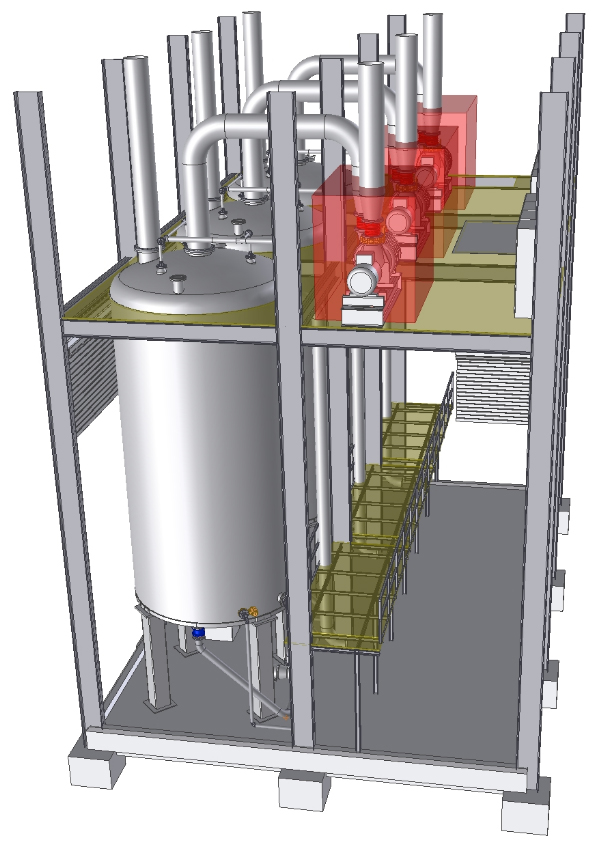

PROREACT C GAS/LIQUID REACTORS

PRODUCT DESCRIPTION

Gas/liquid reactions are performed in many industries such as the chemical, paper, sugar and oil industries. The reaction rates of many gas/liquid reactions are limited by the mass transfer between the two phases. By using the FRIBORATOR high-performance aeration turbines in the PROREACT C gas/liquid reactors very high mass transfer coefficients (kLa) can be realized with low energy input (P/V). Especially, in times of high energy prices and under consideration of the demand for resource-saving production processes this efficiency becomes more and more important.

PLANT DESCRIPTION

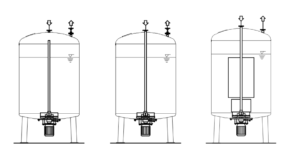

The special rotor/stator technology of FRIBORATOR units combines two functions: Generation of finest gas bubbles, resulting in a very large specific gas/liquid interface and thus mass transfer surface, and mixing with turbulent free jets.

This combination brings some further characteristic advantages:

- Sizes from 20 L to 1000 m3 possible

- for small to medium-sized reactors self-apirating operation without compressor possible

- very high gas yield (with headspace feed up to 100 %)

- low installation effort

- very good mixing performance with low energy input

- combined dispersion, emulsification and/or crystallization processes possible

REACTOR CONFIGURATION

The reactors can suck in gas automatically from the environment, a gas reservoir or from the headspace. In case of very high gassing rates or for the generation of circulating flows, the introduction of special reactor internals may become necessary. A frequently used variant is the installation of a coaxial guide tube, so that the reactor can be operated as an air-lift-loop reactor.

As additional equipment, our FOAMEX foam centrifuges allow safe and efficient operation even if it is disturbed by foam.

Very large reactors are usually operated with blower support to further increase the energy efficiency. Even if the combination of a self-aspirating turbine and a pre-pressure blower increases the complexity of the apparatus, this often pays off due to the lower power consumption. Operation with blower or compressor support is obligatory if the reaction itself takes place under pressure.

HEAT EXCHANGER

Various heat exchangers can be realized for heating up or removing the reaction enthalpies. These range from a simple double jacket to internal spiral and tubular heat exchangers and external circuits.

CONTACT PERSON

Head of Sales