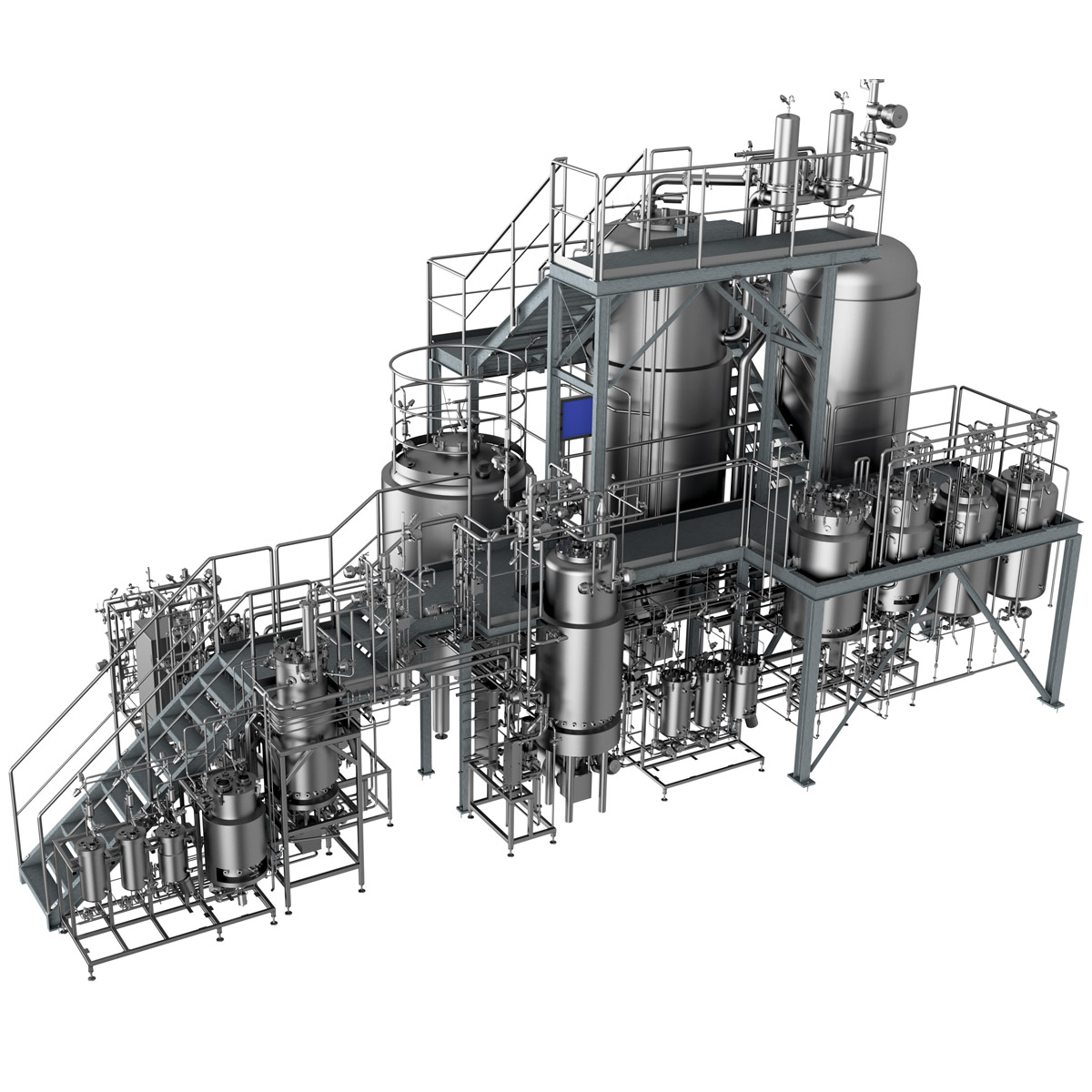

PROREACT “Seed Train”

Defined conditions in series

Most large-scale bioprocesses are carried out in discontinuous batch and fed-batch processes. To start a production cycle, the cleaned and sterilized production bioreactor is filled with sterile medium and then inoculated with active biomass from a cascade of pre-culture fermenters (seed fermenters).

Both production and pre-culture fermenters meet the highest sterile standards and allow the cultivation of microorganisms under defined, controlled conditions.

FRINGS realizes the appropriate “seed trains” for production plants based on customer specifications or based on our own engineering and laboratory work

Seed trains are usually built within a “package unit” with central supply units and with a central control system.

The sizes of the individual stages, the equipment variants, the number and type of control medium templates and the layout planning can be selected in a variety of ways according to customer requirements. Usually, the basic data are determined in the course of pre-engineering in close cooperation with the end customer, the planning company and/or the general contractor.

CONTACT PERSON

Biotech-Team

CONTACT PERSON

Biotech-Team