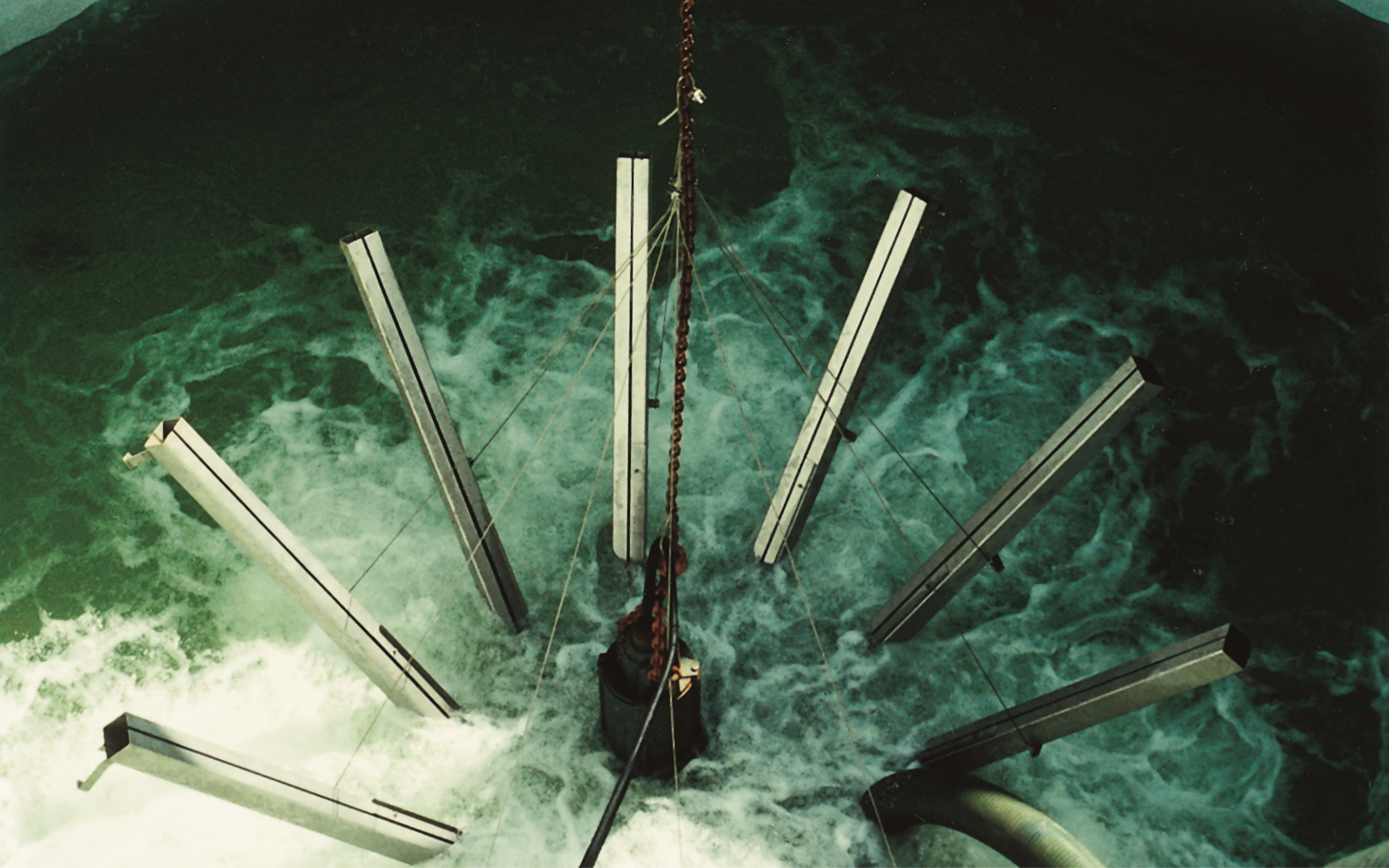

FRINGS SUBMERSIBLE AERATOR

FRINGS has been supplying aeration units for over 50 years. FRINGS rotor/stator high performance aerators enable a fine-bubble air or gas entry into liquids and the permanent circulation of this mixture. Initially designed for vinegar applications, this system was later extended to yeast and biotechnology as well as environmental technology.

FRINGS early recognized that these properties are also of decisive importance in biological wastewater treatment. With the development of the self-aspirating, submersible FRINGS-aerator in 1970, the first aeration unit that mixes air and water in one machine and emits them together was brought to market.

Due to the fine bubble distribution of the air in the waste water, very good oxygen transfer and utilization values are achieved and the microorganisms are optimally supplied with oxygen.

Optimized oxygen input values with “TAK” and “TRG

Based on the operating results achieved by the use of the submersible aerator “TA” in numerous wastewater treatment plants, as well as through consistent research work, the submersible aerator “TAK” was developed. Due to its special discharge geometry with extended discharge channels, it provides significantly improved oxygen input and yield values.

The latest development is our submersible aerator type “TRG”. This aerator type, designed for pre-pressure operation, achieves maximum oxygen input and oxygen yield values and thus meets the current requirements for even greater water depths (10 m and more) and increasing oxygen input capacities.

Numerous operating results and tests have shown that FRINGS submersible aerators provide a particularly high oxygen input into wastewater.

All alpha values determined were between 0.9 and 1.5, which makes the submersible aerators particularly suitable for use in highly loaded industrial wastewater treatment plants.

System Advantages:

- Fine bubble aeration with high oxygen utilization

- Easy installation and maintenance (no tank drainage required)

- High oxygen input and utilization

- Low susceptibility to clogging

- Low noise level

- No spray water development

- Absolute winter resistance

- Thorough mixing, thus also preventing deposits

- Also available in acid-proof steel

Installation options:

Transportable installation

The submersible aerators are placed firmly on the tank or tank bottom and remain stationary due to their own weight. They can be lifted out of the tank by a mobile crane without the need to empty the tank. This is the most common type of installation.

Stationary installation

The submersible aerator is mounted between a bridge or two guide tubes and can be lifted out of the tank with its own lifting device.

Floating installation

It is used in unpaved basins, ponds, lakes or rivers. Here the submersible aerators are mounted on special floating devices. The floating constructions can be anchored firmly, swing back and forth by means of extra-long holding ropes or move automatically on a tightly tensioned guide rope. The installation and removal is usually carried out with a mobile crane.

CONTACT PERSON

Team Environmental Technology

CONTACT PERSON

Team Environmental Technology