FRIBORATOR P AERATION TURBINES

For use in sterile bioreactors

PRODUCT DESCRIPTION

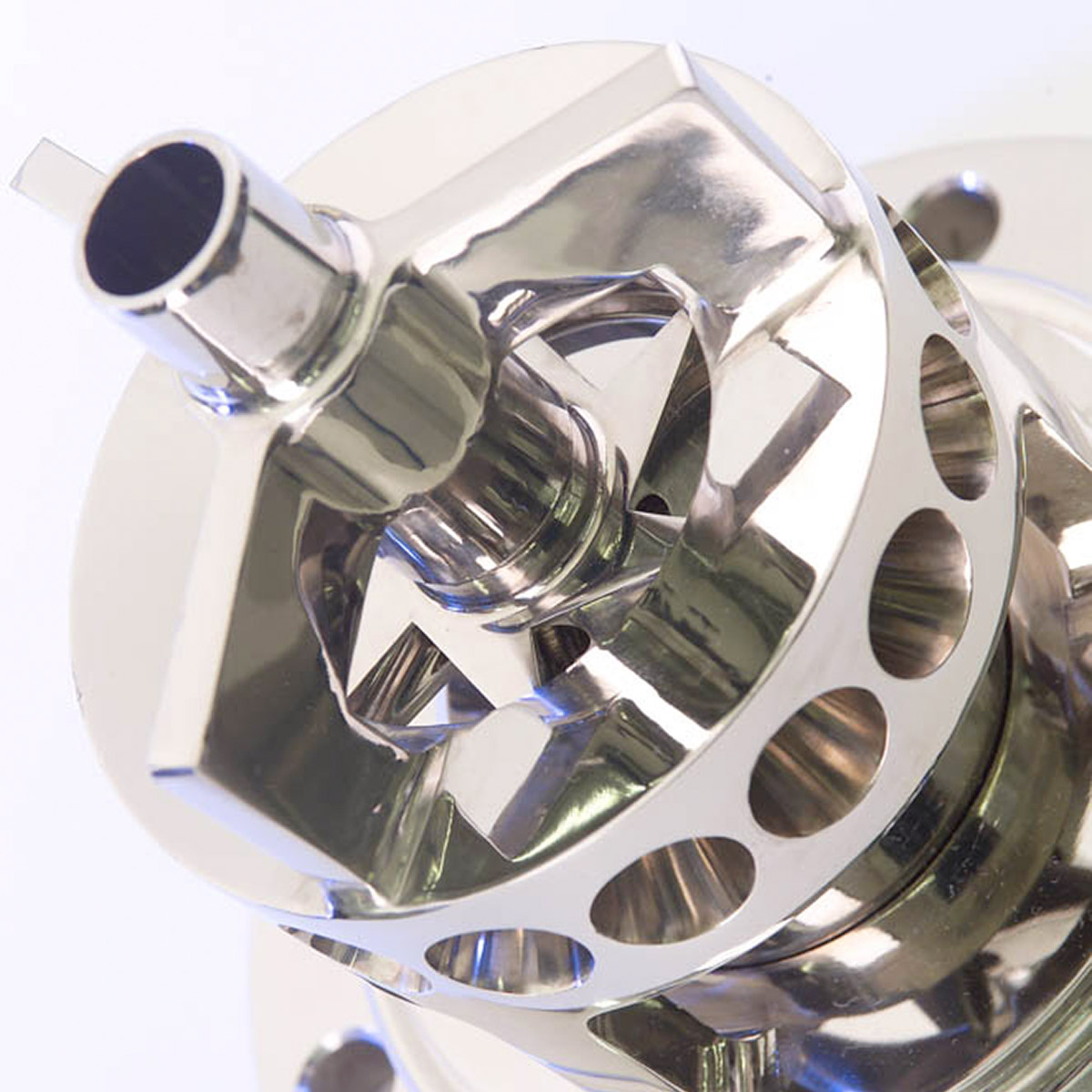

Aeration turbines of the FRIBORATOR P series are designed for small and medium-sized reactors with the highest demands on sterile technology. The special design features of the FRIBORATOR P systems are:

- One-piece rotor and stator made of “solid material”, each with complete draining

- High surface qualities up to a surface roughness of Ra ≤ 0.4 µm with optional electropolishing

- High quality materials (1.4404, 1.4435)

- Pressure stage -1/3 bar or higher

- “Hygienic Design” mechanical seal SiC/SiC double-acting with thermosiphon system for barrier fluid supply with sterile condensate

The advantage at a glance:

- Easy to handle

- High oxygen transfer rates

- Low energy consumption

- Ideal for high cell density fermentations in low viscosity fermentation media

Further advantages of the FRIBORATOR aeration turbines

Like all versions of the FRIBORATOR aeration turbines, the P series has outstanding properties in the production of finest bubble in gas/liquid dispersions for a high gas transfer. Due to the special flow technology also very good homogenizing properties are gained. For hybrid processes or multi-phase media the turbine also has special emulsifying properties.

Of course, the units can also be manufactured from special stainless steels such as 1.4529, Hastelloy or other materials (e.g. high-performance plastics such as PEEK or PVDF) on customer request.

If required, all components can be designed in accordance with FDA or foodstuff regulations. Optionally, materials and production steps are also documented in accordance with the requirements of Good Manufacturing Practice (GMP).

DIFFERENT DESIGN STANDARDS OF FRINGS AERATION TURBINES:

- FRIBORATOR P: for sterile technical processes in biotechnology

- FRIBORATOR B: for hygienic processes in the brewery and beverage industries

- FRIBORATOR G: with equipment and documentation according to GMP pharmaceutical standards

- FRIBORATOR C: without sterile or hygienic design according to chemical standard

- FRIBORATOR TRG: for large reactors (bio commodities, baker’s yeast, …) with additional blower

WHAT ARE FRINGS AERATION TURBINES AND HOW DO THEY WORK?

FRINGS aeration turbines and submerged aerators are high-performance systems for the optimal introduction of gases in chemical reactors, bioreactors and other gas/liquid apparatus.

In particular, these aeration systems are designed for chemical gas/liquid reactions in the low-viscosity range and for oxygen supply of bacteria and yeast cultures.

High performance for an optimized reaction speed

The mass transfer of gas into the liquid is often the rate-limiting step in gas-liquid reactions.

With FRINGS aeration turbines it is possible to increase the speed of this mass transfer compared to other aeration systems.

In chemical reactions this means an increase in the reaction speed and in microbial processes an increased growth and product formation rate.

Minimum installation effort and optimized energy consumption

Our gassing turbines and submerged aerators are characterized by their ability to draw in gas automatically. In many applications, a gas compressor/blower can therefore be omitted and a plant design is possible with minimal installation effort. Even if an additional blower generating pre-pressure has to be installed, suitable control results in extremely efficient systems with very low specific energy consumption.

Operation of the FRINGS gassing system

In FRINGS gassing systems, the star-shaped rotor located at the bottom of the tank to be gassed sucks in liquid axially and accelerates it radially and tangentially at the working surfaces.

A vacuum area is created on the rear side of the working surfaces, which are connected to the gas line, during rotation. Due to the pressure difference compared to the gas pipe, gas flows out into the working area of the rotor and is intensively mixed with the liquid.

The liquid/gas mixture is conveyed into the channels of the stator. At the channel outlets, whose length and geometry depends on the diameter of the tank and the rheology of the medium, the mixture flows out turbulently.

CONTACT PERSON

Biotech-Team

CONTACT PERSON

Biotech-Team