FOAMEX FOAM CENTRIFUGES

The solution against foam for your closed systems

PRODUCT DESCRIPTION

Foam can cause enormous problems in process plants and reactors. We offer a solution for closed tank systems. With our FOAMEX foam centrifuges, foam is separated into two fractions exclusively by mechanical action principles. The liquid remains in the system and the gas can escape.

Foams are produced in many processes, e.g. by gassing a medium, by reaction gases released, by vacuum gas discharge from a medium or during the expansion of a container. It is often necessary to control the foam quantity to prevent contamination of downstream equipment such as filters or pumps.

With the help of FOAMEX mechanical foam centrifuges, foam control can be achieved in most cases without the addition of chemical antifoam agents

This often results in advantages not only in the foaming process itself, but also in downstream processing of the antifoam-free media.

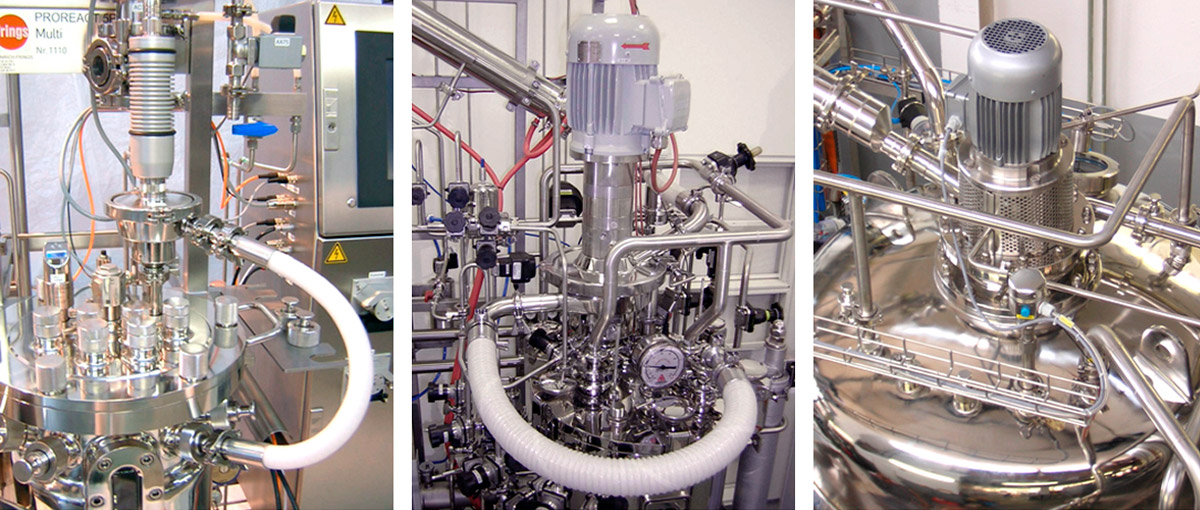

We offer our foam centrifuges in different construction types, whereby the main differentiation is based on the choice of material, pressure level and design, especially with regard to hygiene requirements.

Easy integration into the existing system

The foam centrifuges can be integrated in the reaction or fermenter tank directly into the dome lid. For smaller systems or for retrofitting, installation in the exhaust pipe is recommended. In this way, a decentralized integration of the foam centrifuges into the plant can be realized without having to modify the tank.

Mode of operation of FOAMEX foam centrifuges

FOAMEX foam centrifuges separate foams with a liquid content of up to 30% (in individual cases even more) into a liquid-free gas stream and a low-gas liquid phase, the foam concentrate.

The foam concentrate is either returned to the reaction vessel or discarded.

DIFFERENT DESIGN STANDARDS OF FRINGS FOAM CENTRIFUGES:

- FOAMEX P: for sterile technical processes in food and biotechnology

- FOAMEX B: for hygienic processes in brewery, baker’s yeast and beverage industries

- FOAMEX G: with equipment and documentation according to pharmaceutical standards (GMP)

- FOAMEX C: without sterile or hygienic design according to chemical standard

APPLICATION REFERENCES

FOAMEX systems perform inconspicuously but efficiently in many applications. Since we know that virtually every foam behaves differently, we always design the foam centrifuges specifically for the application.

To determine foam characteristics, we have special mobile measuring systems and rental units.

- FOAMEX P: Fermentative production of e.g. amino acids, bioplastics, cosmetics, enzyme production, etc.

- FOAMEX B: Brewery tanks, CO2 recovery, tea extraction, vacuum degassing, yeast production, etc.

- FOAMEX G: Pharmaceutical processes with recombinant bacteria and yeasts, filter protection, etc.

- FOAMEX C: Paper, paint, plastics production, biogas plants, wastewater processes, etc.

CONTACT

Biotech-Team

CONTACT

Biotech-Team